California Transplants in Newman, CA was established in 1997 when Ted Woods, a grower with more than three decades of experience in the vegetable transplant industry started his business. Today the farm operates under approximately 1.9 million square feet of plastic. The plastic we’re referring sits atop the 274 greenhouses that California Transplants uses and maintains on their 100-acre farm.

Transfer cart travels between houses and is filled from both sides

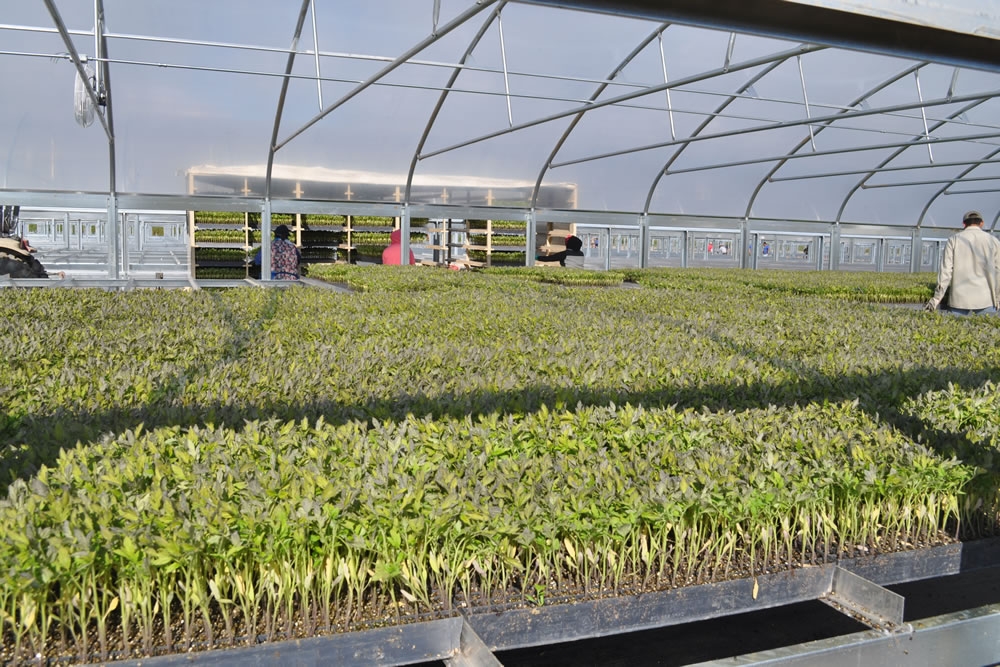

“Tomatoes grown for processing purposes make up 95% of our business and the other items we grow such as fresh market tomatoes and broccoli fill in some of the gaps,” Woods said. “These fill-in crops will change based on our customers’ needs.” In the past, California Transplants has grown things such as peppers, cauliflower, melons, cabbage and many other specialty crops over the years.

The business model at California Transplants is all about expediency, quality and convenience. “The farmer brings us the seeds and we germinate them, grow the plants and ship it to him,” Woods said. “We get the orders well in advance and then we fill them, so we never grow anything unless our farmers want it. We have eight salesmen that cover the state and our crew varies based on volume and the time of year. We’re in an ideal location, because of our dry and arid site above the valley fog. And due to our central location, we’re able to deliver our transplants to the field with little turnaround time.”

Benches partly emptied through drop down sidewalls

By closely monitoring the seeding, germination and transplanting of all its plants, California Transplants produces hearty seedlings that grow into healthy crops. By maintaining a clean, carefully controlled growing environment Woods and his crew are able to give its customers a disease-free start plants to their growing season.

“Fresh market” tomatoes are tomato transplants that are grown by California’s customers that are farmers primarily in California to ultimately be sold in grocery stores statewide. “Processing” tomatoes are also transplants, but in the end they go to canneries to end up as tomato paste, sauce diced tomatoes and ketchup, to adorn hamburgers and French Fries worldwide.

After working for other growers for almost 20 years, Woods decided to make the leap to owning his own operation, when a group of investors approached him. “They asked me to start my own business and my contract had just expired with my former employer, so I said yes and put it all together. It’s been a very successful endeavor and I enjoy it. As long as I want to keep doing it, I have no plans to retire. I don’t really know what I would do if I was retired, because I’ve been doing this for so long.”

Benches full ready for off loading

Ted’s son Mark worked for his father for many years until he came one day he went to his dad and told him that he had what you might call “growing plans.” “Mark worked for me and helped me to set up California Transplants and then it was time for him to move on and get his own thing started (Woods Transplants) and that has been great.”

Woods started working with Agra Tech when he founded California Transplants and “It has worked out well for all of us and it’s a great relationship,” he said. “Of the 274 greenhouses we have, all but 19 of them are from Agra Tech. Jim Bergantz, our rep from Agra Tech sells them to us; John Pound advises us: Anita Pound helps to engineer the structures and Ray Pound’s company Ag-Con in San Jose, CA does all of the construction. The people at Agra Tech are easy to work with and every time we’ve gone to them with requests, design modifications and things like that—they’re always willing to make it happen for us.”

Written by Ed Attanasio

TrustED Advertising

Published on:

11/10/2015

Post by:

Admin

Category:

Controlled Environment Greenhouse

Greenhouse Structure

Greenhouses

Transplant Houses

Vegetable Growing

Tag(s):

#Agra Tech

#California Transplants

#Greenhouses

#Growing plans

#Jim Bergantz

#John Pound

#Ted Woods

#Tomatoes grown

#Vegetable transplant industry

Working with Agra Tech’s Sales Engineer Jim Bergantz throughout the entire planning process was also a major plus, Breen said. “He was so professional and knowledgeable, he was great. Jim knows the industry and his company’s products very well, and communicated well with us during every stage to make sure that we got exactly what we wanted for our application.”

Nutrien Ag Solutions

John Breen

Director of Research and Development

Biola, CA